Power analysis is a complex field, which requires a solid understanding of various parameters and calculation algorithms. Our OXYGEN measurement software provides you with a powerful and comprehensive power analysis function, enabling you to turn DEWETRON measurement equipment into a mature power analyzer. However, before starting, you should be familiar with the basic knowledge of performance analysis and how to seamlessly integrate it into OXYGEN. This blog post introduces how to effectively use OXYGEN performance analysis function.

Three phase power system analysis

First of all, the following analysis assumes a three-phase power grid, because it is still a common method for power generation, transmission and distribution. Although polyphase engines with more than three phases have an obvious development trend, three-phase engines are still commonly used.

Note: We answered the question "What is three-phase power supply?" in the previous blog Power Pack and Power Pack The difference between!

To start power analysis in OXYGEN, you need to physically connect the three-phase system to DEWETRON power analyzer 。 You can select DELTA or STAR configuration.

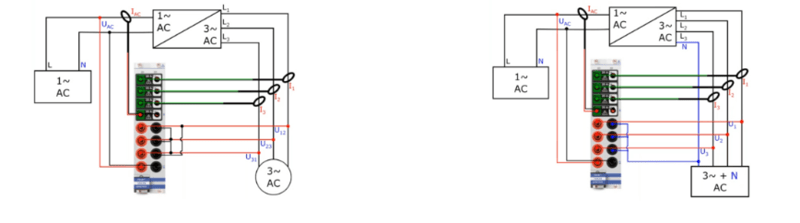

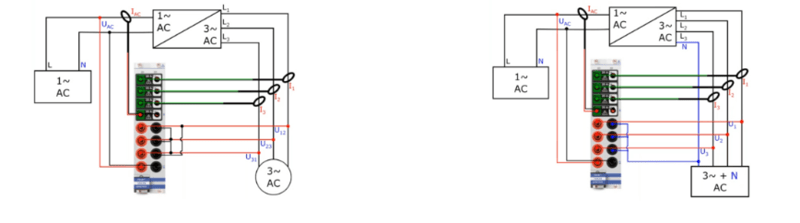

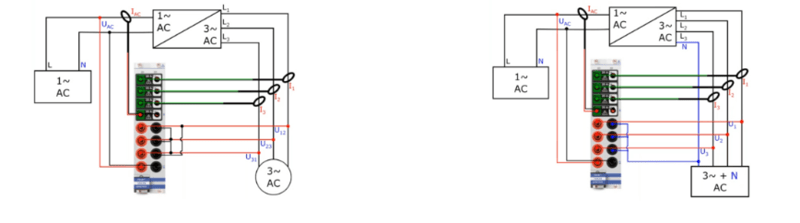

Angular configuration

DELTA configures the measurement line to line voltage. In other words, DELTA is configured to measure the potential difference between lines, where a single line represents a single conductor. In the case of a three-phase system, there are three lines.

Star configuration

Another way to set up power analysis is the STAR configuration, which has an additional line neutral conductor (see Figure 1, right panel). In the STAR configuration, you measure the phase line voltage, which means that you measure the potential difference between any line and the neutral conductor. If the neutral line cannot be accessed in STAR configuration, we recommend using DELTA configuration.

The configuration type does not affect the measurement results. When you use DELTA configuration, our measurement software will recalculate the phase to phase voltage and output STAR voltage. For the rest of the text, we assume that DELTA configuration is implemented.

Measure with DEWETRON power analyzer

By using DELTA connection, the power analyzer's Power module Measure the series voltage and current. However, depending on the current intensity (e.g. for large currents), it is necessary to current sensor 。 You can also choose to measure the current indirectly, for example, using a zero flux current sensor. If yes, the voltage and current of the inverter shall also be measured.

How to connect the current sensor?

To measure the high current value, the current sensor must be connected in OXYGEN. Depending on whether the current sensor has voltage or current output, you can use different measurement modules. For example, when processing a current sensor such as LEM IN 500, you need to configure the required number of secondary turns inside OXYGEN. You can find this value in the data table. When you access the module's settings, enter the number of secondary turns in the zoom field. This constitutes the entire configuration process required before using the current sensor in OXYGEN.

If you have different current sensors or use your current sensor for each measurement task, you can also set it as a sensor in the sensor database. There, you can store the sensor and its configuration for use when needed. This saves valuable time in the system configuration process.

Power group in OXYGEN

In OXYGEN, the power group operates as a calculation group to calculate the power parameters of the selected voltage and current channels. You can freely define the channels to be used for calculation. For example, you can specify a motor as a power group.