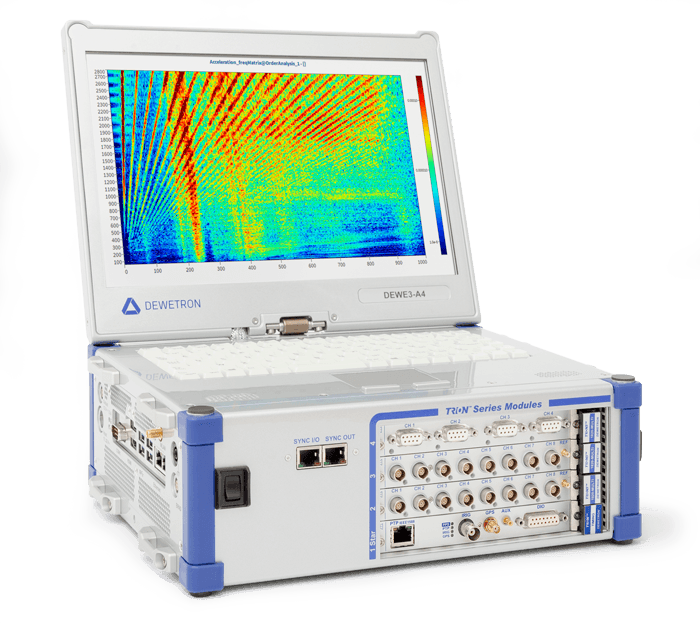

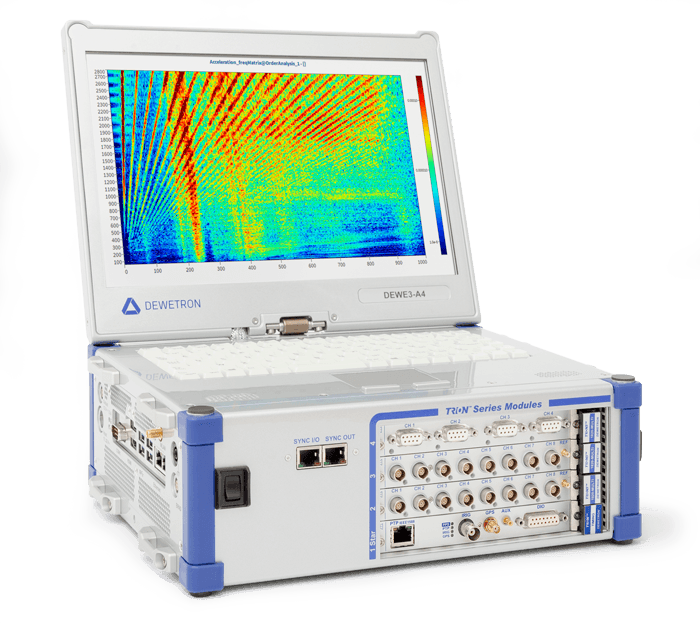

Many customers are choosing Dewetron In data acquisition, precision and resolution (digits) are often intertwined. Some confuse resolution and precision, believing that high resolution must represent high precision. When selecting a Devtrong data acquisition board, you can easily determine the number of analog input/output and digital signal channels you need. However, it is not so easy to determine the resolution of the analog input channel. Some Dewetron 12 bit boards can achieve higher performance sampling rate , or it has a lower price than similar 16 bit boards. How to determine which card you really need? To make the right decision, you need to consider the overall accuracy required by the system and the board.

First consider accuracy rather than resolution

Engineers often rely on "guess" when deciding whether to use the 12 bit or 16 bit data acquisition equipment of DVC. In fact, through many methods, the overall accuracy required by the data acquisition card can be measured by the given system accuracy index. In a given range, the measurement result of a 16 digit data acquisition card of Dewei Chuang has the 16th power of 2, that is, 65536 possibilities, while the 12 digit data acquisition card has the 12th power of 2, that is, 4096 possibilities. In an ideal state, these possible values are evenly distributed throughout the measurement range. The measurement hardware classifies the actual values into near possible results and returns the results to the computer memory. If the calculation accuracy only considers this point, then the 16 bit measurement is always 16 times more accurate than the 12 bit measurement (=2 to the 4th power). In fact, people only regard this error as one of the factors affecting the accuracy. Since this error is introduced in the process of converting analog quantity into digital quantity, we call it digital quantization error. The digital quantization error accounts for 35% of the total measurement error of the 12 digit acquisition card, but the proportion of the measurement error of the 16 digit acquisition card is negligible. Especially in 16 bit measurement, you must consider other error factors besides measurement error. The so-called other errors include noise, nonlinear transfer function, temperature drift error and more. All these errors will be affected by the design quality of the electronic circuit for processing analog signals, which is an important factor in the overall error of 16 bit products. This means that the analog design of 16 bit board is more strict than that of 12 bit board, especially at high gain. Different measurement hardware manufacturers have different definitions and terms for composition error. Therefore, you must check the technical specification list of multiple suppliers to confirm that the manufacturer has not missed any important information that affects the accuracy.

Influence of conditioning and sampling module on precision

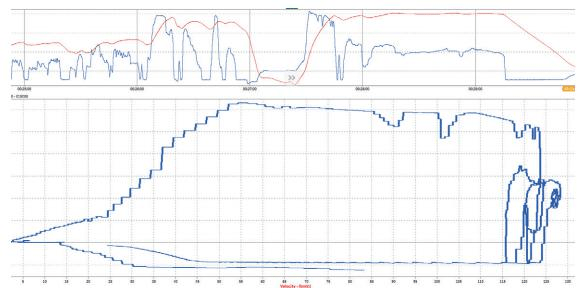

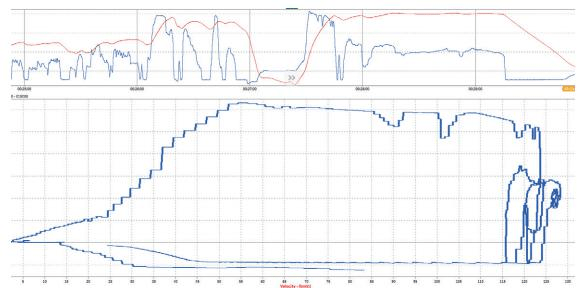

The temperature of the instruments and equipment on the computer or workbench will fluctuate constantly, and the high-quality DVI data acquisition equipment can ensure the measurement accuracy within a considerable temperature range. Generally, 55 ℃ is the working range of PCI devices. The customized resistor network and high-grade components can limit the temperature drift to 6 ppm/℃. Another important design is resolution improvement technology. Devitron data acquisition equipment shall be designed to minimize the noise and uniformly distribute other errors according to the Gaussian rule. Therefore, the measurement accuracy of such equipment can also be greatly increased by averaging the sampling results. After calculating the average value of 100 or more sampling results, the 12 bit board can have the effect of 14 bit board, and the 16 bit board can have the effect of 18 bits. The disadvantage of this method is that the existing hardware is used to improve the accuracy, while the real-time performance of the system is lost. Therefore, such methods cannot be used to improve the accuracy in the testing occasions with strict real-time requirements. The data acquisition equipment with multi-function I/O shall have calibration circuit to correct the gain and drift error generated by analog input and output. You can use OXYGEN Software to eliminate time drift and temperature drift during operation. Without external circuit, the highly stable internal reference voltage on the board can ensure its original accuracy and stability under time and temperature changes. The factory calibration constant is stored in the EEPROM on the board and cannot be modified. The user adjustable constant is saved in the modifiable part of EEPROM. You can restore the equipment to the original calibration state when it leaves the factory by taking out the non modifiable constant.

Software Importance

Quality of configuration and drive software Quality is as important as the quality of measurement hardware. Be patient and careful to select a stable and long-term tested driver software for your data acquisition and signal conditioning system. The OVYGEN software can help you quickly complete the equipment installation and start measuring data. Before purchasing, please refer to some measurement examples to make your application system development have a high starting point. In order to ensure the investment, the driver software should be able to maintain the same high performance and ease of use under a variety of different development environments, operating systems and computer buses. Spending time evaluating and selecting the right data acquisition equipment is the key to successfully measuring any signal and sensor. Although you may have many choices, each kind of data acquisition card has its unique design, so there is only one choice. Consult with the technical support engineer to understand the working state of the equipment at different temperatures, how noise resistance is, and whether the software provides quick configuration tools, etc., so that you can be more confident about the product quality and even the success of the project.