Market demand

With the development of technology, the efficiency and power requirements for motors and electric drive systems are very stringent nowadays. Therefore, it is essential to calculate power and efficiency online for highly dynamic measurement of current and voltage. Especially in the development process of electrical components, motors, transmission systems or whole vehicles, original data must be stored to further analyze power parameters. Cost constraints, limited resources and innovative companies that become new competitors in the OEM market increase the pressure on decision makers and users

In order to deal with this pressure, an innovative, time-saving and easy to adjust measurement technology is needed. Traditional power meters and traditional user interfaces have become limited in meeting changing technical requirements. The purpose of this paper is to introduce the typical problems in motor and transmission system testing, as well as the solutions and advantages of DEWETRON using new hardware and software technologies. These new technologies help address today's challenges in efficiency, accuracy, cost, and time requirements.

>New methods of hardware and software technology

>Modularity and flexibility

>High performance power analyzer meets dynamic analysis requirements

>High dynamic makes measurement range setting simple

>High precision dynamic voltage input channel

>Simple configuration saves time and avoids wiring errors

Modularity and flexibility

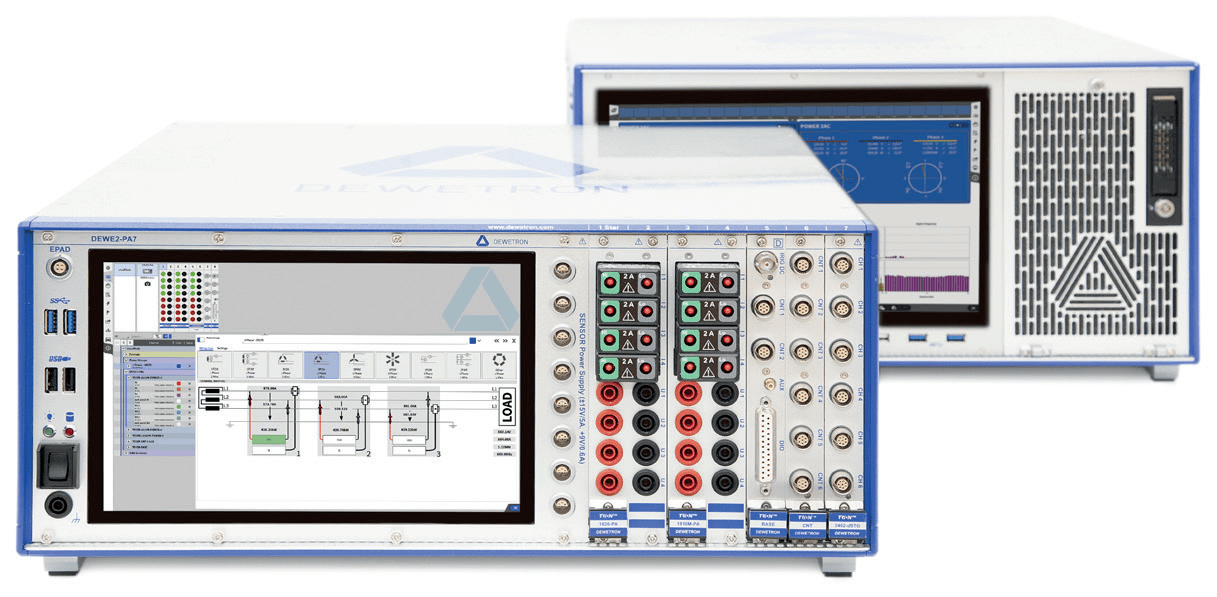

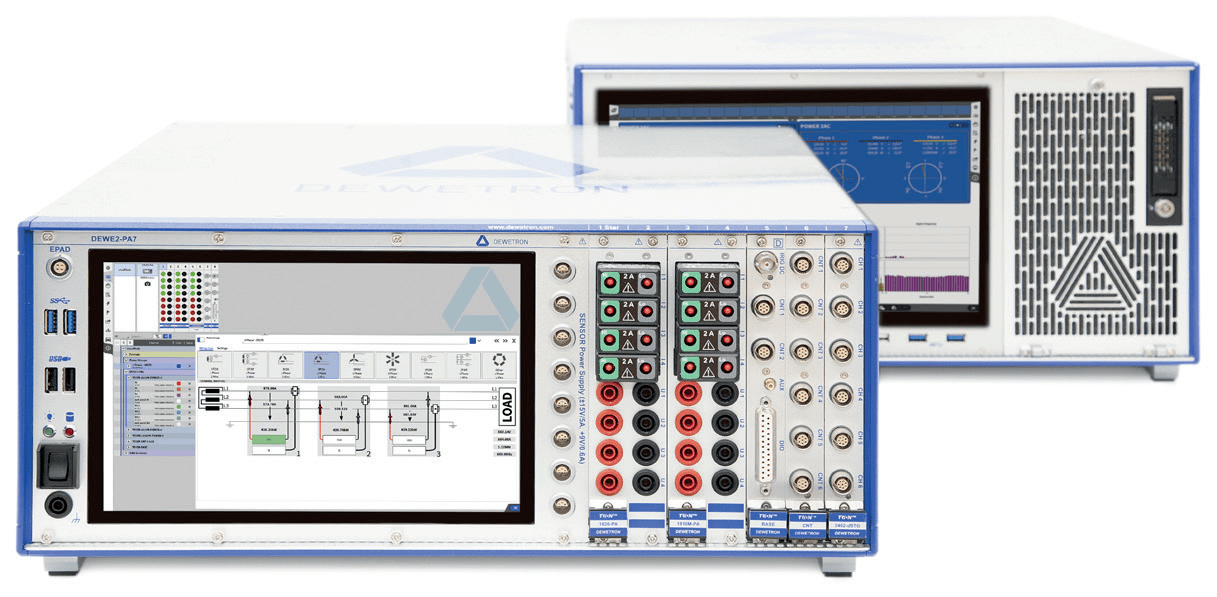

Nowadays, 6-phase or 9-phase motors are widely used in high-efficiency transmission systems. Therefore, it is impossible to analyze the whole transmission system with the traditional power analyzer. In addition, the traditional power analyzer requires expensive costs to achieve expansion and synchronization, and additional software authorization and metering calibration costs. Two high-performance power analyzers from DEWETRON DEWE2-PA7 and DEWE3-PA8 It can meet the development needs of engineers and measurement technology. Only one DEWETRON power analyzer There are as many as 16 high-precision power test channels, and the power calculation can analyze the 9-phase system. It can conduct online or offline power analysis on multiple power groups (DC or AC), and analyze the mechanical and environmental parameters (such as speed, torque and temperature) completely synchronously, and complete the analysis of motors, batteries, inverters, Test and analysis of the whole transmission system and the whole vehicle. DEWETRON power analyzer can replace multiple systems to complete their tasks through unparalleled modularity and flexibility. Using a set of system can reduce training and debugging time, save the cost of measurement calibration and software authorization, save valuable development time, and ensure that all data have a uniform data format.

High dynamic makes measurement range setting simple

In the process of motor development and testing, a lot of tests are needed to determine the stability, performance and efficiency of the motor. During this test, the power transmission system will start in various scenarios and be evaluated with the help of performance indicators. If the traditional power analyzer is used, if a wide measurement range is selected to adapt to the test signals in different scenarios. This can lead to inaccurate accuracy at low loads. Therefore, the configuration must be modified according to different scenarios, which increases the time required for configuration and blocks the test bench for a period of time that is not needed. DEWETRON Using dynamic, high-precision high-voltage input channels, you can accurately test the high voltage from several volts to+/- 2000VPeak with only one measurement range. Make it unnecessary to adjust the measuring range. In addition, this also avoids or reduces errors and time when setting the "correct" range. In addition, the disadvantage of measurement range conversion (transition range, no continuous measurement data) is eliminated.

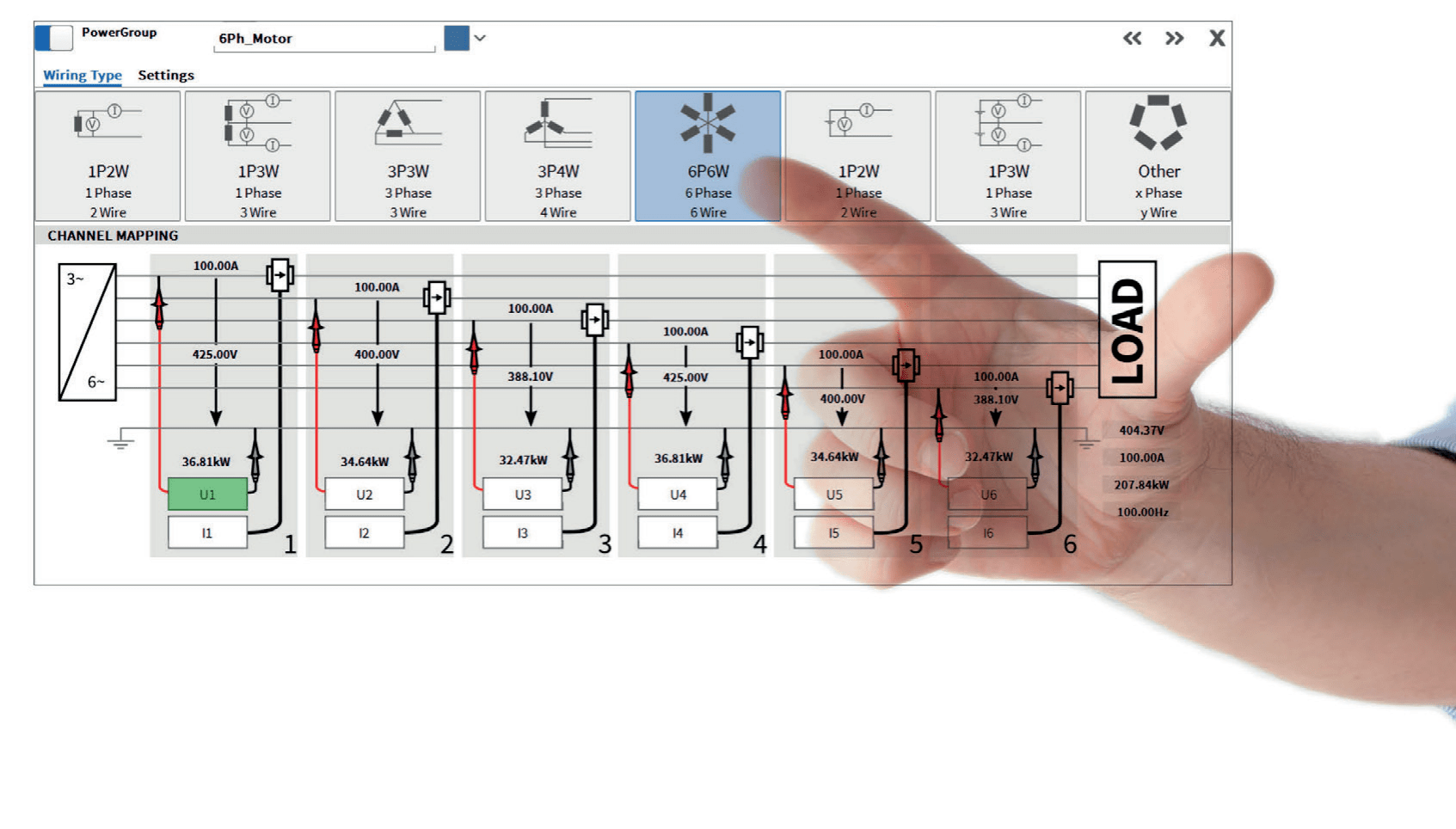

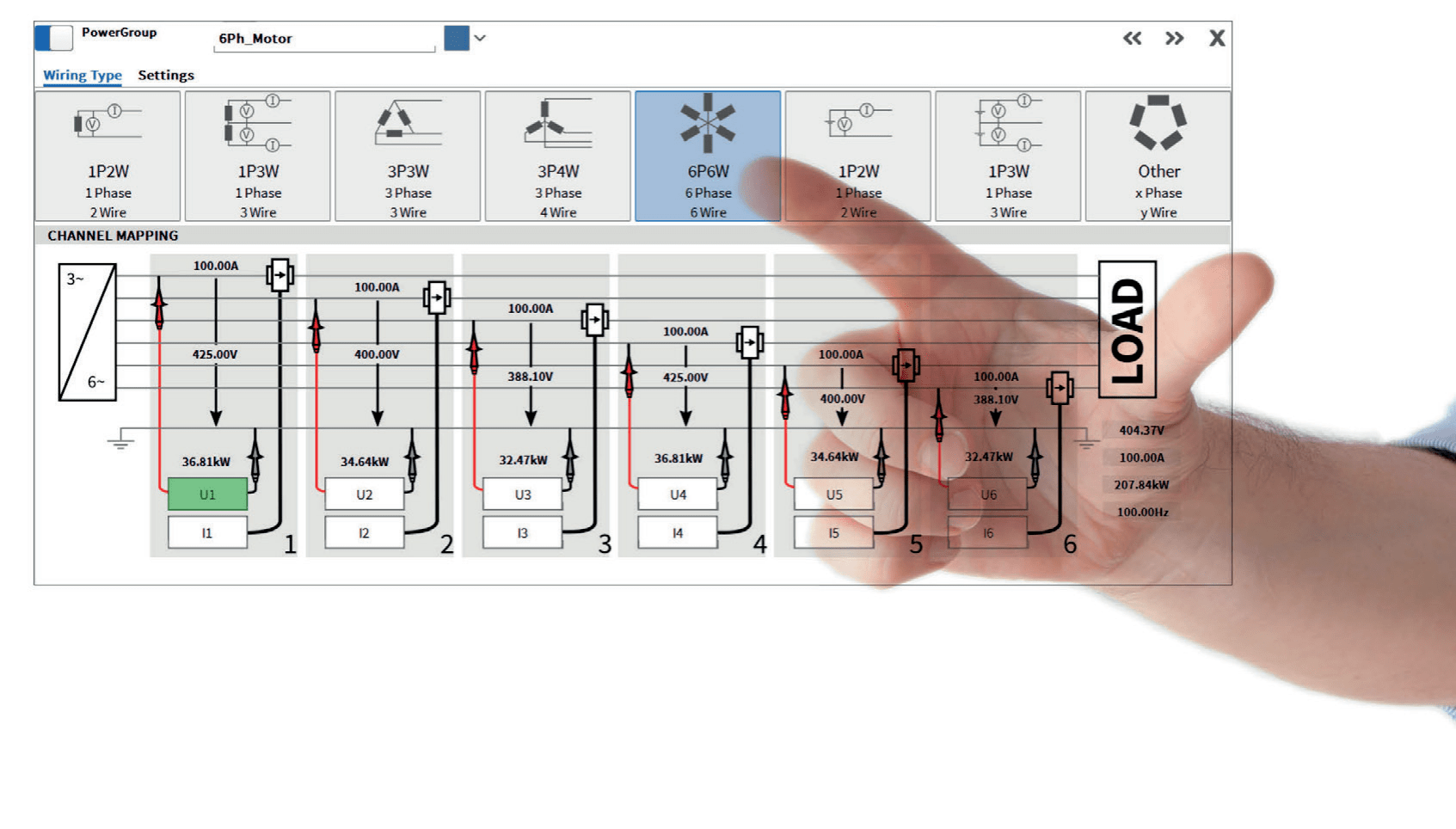

Efficient configuration and avoiding wiring errors

As tests or test structures become more and more complex, the potential for wiring errors and "configuration errors" is increasing. Bad situation, which may cause the data to be unusable and need to be retested, thus increasing the incalculable cost. Test software of DEWETRON OXYGEN Its power calculation options can intuitively and logically assign each electrical system to a power calculation group, and flexibly assign physical inputs to various predefined circuits. Each parameter is visualized during configuration, so that wiring errors can be checked before actual testing. Therefore, faults can be identified early and quickly and solved in software configuration without changing physical voltage and current input.

DEWETRON Solution

With DEWE2-PA7 and DEWE3-PA8 as well as the entire DEWE2 and DEWE3 series of equipment, DEWETRON provides professionals with high-performance, high-precision, user-friendly "tools" with intuitive operation and simple configuration. Whether used in the lab or fully integrated into Test bench Or in the automation system DEWETRON data acquisition system With its flexibility, configuration convenience, a variety of intelligent interfaces and protocols (such as XCP, SCPI or EtherCAT) to ensure the intuitive operation, remote control and even the automation of test procedures to gain the trust of engineers. Whether testing single or multiple motors, batteries or inverters, DEWETRON power analyzer is the choice for testing electric drive systems today and in the future.

>A single power analyzer can carry out polyphase power analysis of up to 9 phases (usually only 3 phases or very troublesome post-processing).

>At the same time, calculate the DC or AC power of multiple power groups online (the fundamental frequency can reach 200KHz, while other power analyzers usually only reach 900Hz).

>In the power analysis calculation, the efficiency and performance of up to 16 power groups are determined online (usually only 4-6 power groups).

>Variable synchronization source (usually the synchronization source is fixed).

>The raw data is stored without gaps (usually only the statistical values within a period of time can be stored).

>The power analyzer can be used independently and integrated (various chassis used for vehicle testing).

>Advanced interfaces and protocols make it easy to integrate and remotely control (such as XCP, ASAM,MDF4,SCPI)。

>Only one data source and one data format are used to replace 2-3 old systems (data recorder, oscilloscope, transient recorder, power meter).

>Significantly reduce the cost of training, measurement calibration, maintenance and software authorization (only one system and one software are used to analyze the entire transmission system).

>Simple configuration and operation can save a lot of time, thus freeing up resources for other important tasks.

>Improve efficiency and reduce losses through accurate, reliable and traceable performance analysis.

>Through standard interfaces and protocols, it can be easily and time-saving integrated into the automation system.