Application of DVC data acquisition in M2VP multi-stage double shaft compressor test bed

Introduction of multi-stage double shaft compressor

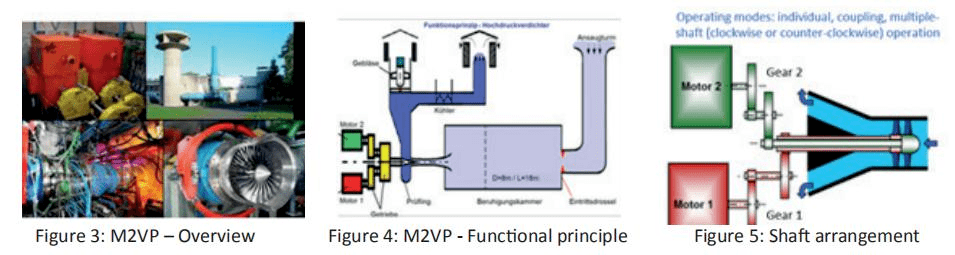

The application of this key propulsion technology research institute is about the experimental research of axial compressor, measuring the compressor performance diagram and detailed flow field. In addition, the institute has also carried out special applications such as active noise control or counter rotating prop fans. For the research of axial compressor, the multi-stage double shaft compressor test bench is used to study single-stage and multi-stage compressors. In addition, the measurement of the combination of low-pressure and high-pressure compressors was also carried out. The propulsion unit consists of two motors. These two motors work on two concentric running shafts on the compressor test bench through a gearbox combination. Each motor can adjust the speed independently (continuously) in any direction from 0 to 2000 rpm. Depending on the combination of transmissions, the speed can reach 20 000 rpm. Each motor has a power of 5 MW at nominal speed and 10 MW in coupling mode.

The air pipe system of M2VP multi-stage double shaft compressor may have two different working modes, open loop and open loop with blower:

Operating mode 1: open-loop

This mode of operation is suitable for general compressors, such as multi-stage axial compressors with average pressure ratio. The chamber is filled with air by the suction tower. From the chamber, advection air is injected into the test compressor. After testing the compressor, air passes through the outlet pump valve and is sprayed into the environment. The inlet pressure can be further reduced by a nozzle between the suction tower and the chamber. In this way, compressors of more than 10 MW can be studied.

Operating mode 1: Open loop with air blower

The second mode of operation is applicable to compressors with small total pressure ratio and corresponding high mass flow, such as fans or prop fans. The difference from the open loop operation mode is an additional blower, which is installed in the outlet pipe. This overcomes the pressure loss caused by wall friction in the air pipe system. In this operating mode, the mass flow rate may reach 160 kg/s.

For this application, many different values were measured, some of which were:

>Static wall pressure and total pressure with piezoresistive sensor

>Total temperature with thermocouple

>Strain value (128 channels, measured by Dewetron data acquisition system)

>Vibration measurement using accelerometer

>Different flow rates and fluctuations

Recommended products:

Data acquisition host of Dewei Chuang DEWE3- RM16 128 channels, 8 TRIONS or TRION3 Series module