Application of Dewei Chuang data acquisition in the condition monitoring and data acquisition project of the test bench of an aeroengine research institute

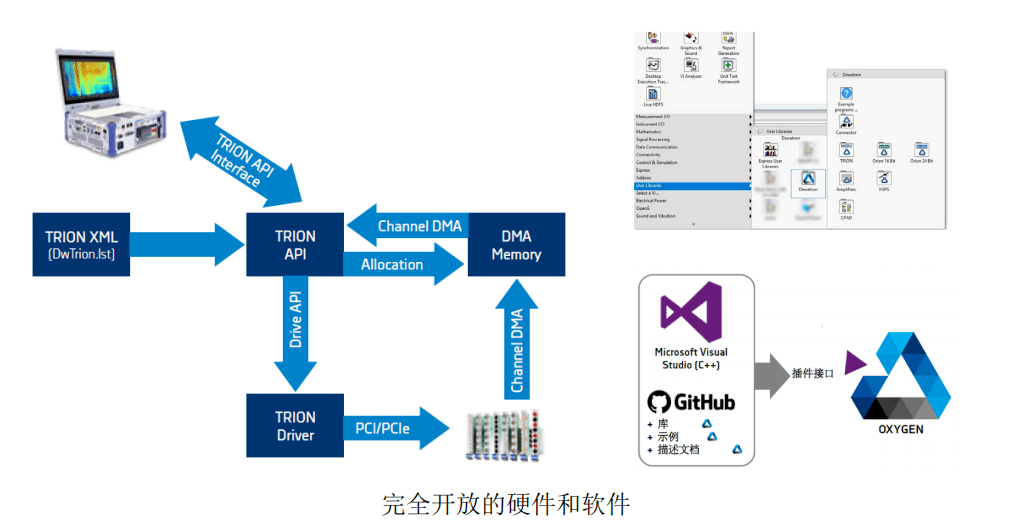

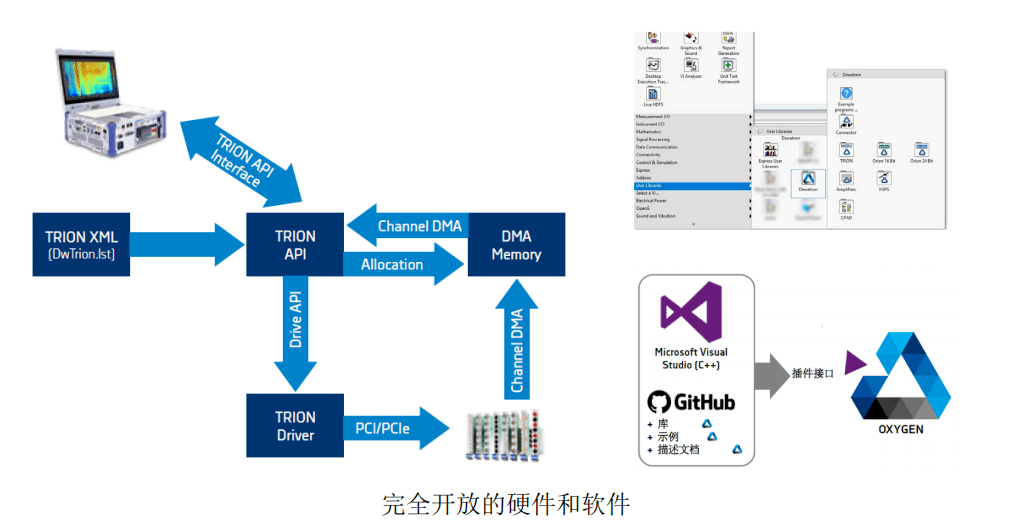

Faced with the complexity of test tasks, the diversification of signal types and the deepening of analysis methods, test equipment not only needs to ensure the accuracy of hardware and the stability of acquisition, but also needs to be more suitable for the use needs of R&D testers. On the basis of the intelligence of the equipment itself, it is necessary to open its own hardware and software interfaces to adapt to more types of signal access and personalized function development by researchers.

DEWETRON test system is optimized on the open interface of hardware and software in order to meet the developing test requirements. Based on the open hardware platform and software system, R&D and testing personnel can carry out targeted function development to simplify the test process, optimize the calculation method, and make data transmission and processing more flexible.

Customized development cases

Test bed condition monitoring and data acquisition project of an aeroengine research institute

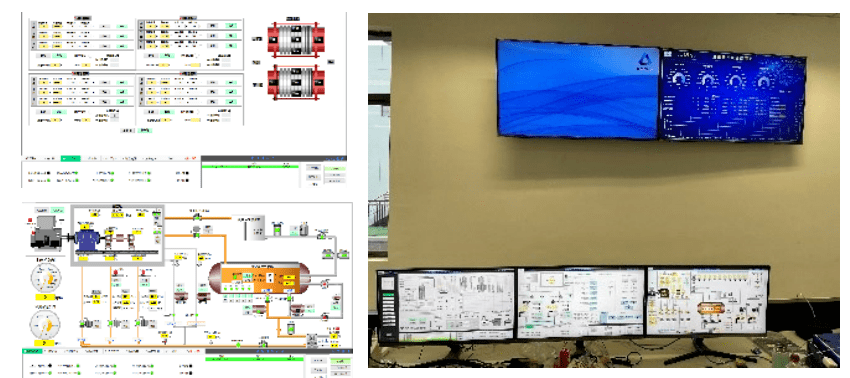

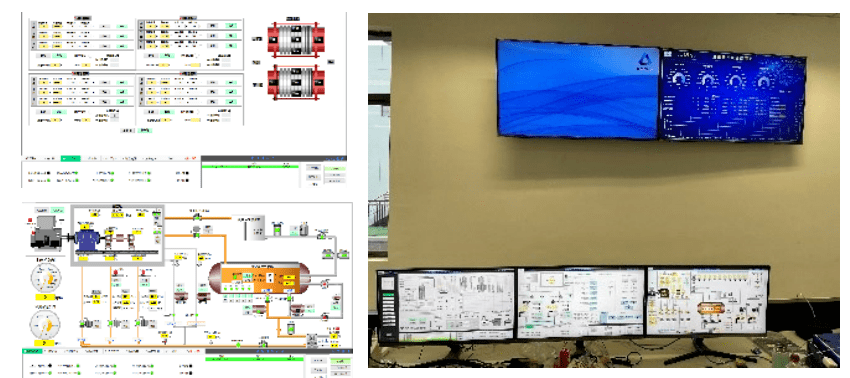

Project requirements: need to be based on DEWETRON Acquisition system, develop a set of condition monitoring and data acquisition software. It is used to visually display the hardware composition of the test bench, operating parameters of each component, valve status, oil/air flow direction, pump speed, temperature and other parameters. At the same time, the vibration signal, strain signal, pressure signal, strain signal, etc. need to be collected, monitored and saved.

Purpose:

➢ Control and status monitoring of test run personnel;

➢ Lead the inspection of test tasks and results;

➢ Experts' attention to the specified test parameters;

Customized development control/status detection/data display/data storage software (fuzzing has been carried out)

Capacity improvement:

➢ Self developed software, and OXYGEN Data communication and interaction;

➢ Embedded software interaction, data communication and analysis program;

➢ Online monitoring of test process and status;

➢ Visual display is easy for visitors to display;

➢ Experts can independently obtain the designated test channel for display;

The use of open hardware and software platforms will further enhance:

➢ Special formula calculation ability (user-defined embedded plug-ins, data processing);

➢ Data interaction with third-party equipment and OXYGEN software control (such as three times of six gear manual verification of non-standard sensors; automatic verification of loading station command interaction)

➢ User defined analysis of sensor and signal commands such as UDP/TCP/RS serial ports;

➢ Export of special data formats;

➢ Call the hardware SDK and use the existing mature self-developed software for hardware configuration and data reading;