Maintenance is essential for all types of equipment - cars, aircraft, industrial equipment, coffee machines, etc. Calcification, dirty oil condensation, bridle rubber tear and so on all will damage your equipment, reduce performance and increase cost. Therefore, good equipment and machine maintenance is very important to extend the normal operation time of equipment and improve efficiency, which will bring higher benefits.

What is maintenance?

First, let's clarify what maintenance is or what we mean when we talk about maintenance here. Generally speaking, maintenance includes all maintenance, repair and overhaul (MRO) processes. This includes any activity aimed at retaining or restoring functional units, equipment or machines. Various examples:

Replace the engine oil;

Clean the HVAC system regularly;

Lubrication of rotating device;

Washing machine decalcification;

Replace defective parts in the manufacturer;

…

How to distinguish maintenance work?

As mentioned earlier, not all maintenance work is the same. Generally speaking, there are two basic types of maintenance:

Preventive maintenance - regularly arrange equipment inspection and service

Corrective maintenance - repair or replacement of equipment after failure, wear or failure

1. Preventive maintenance

Preventive maintenance refers to scheduled maintenance. The goal is to fix and find small problems before they become big problems. Ideally, nothing will fail and your device will operate normally between scheduled services without any failure.

The concept of preventive maintenance can be further refined, so it can be subdivided into specific subtypes:

Condition based maintenance

As the name implies, condition based maintenance depends on the condition of the equipment. Execute it when there is an indication that the performance of your device is declining, or a part of your device will fail.

Planned Maintenance

Planned preventive maintenance, also known as planned maintenance or planned maintenance, is any planned maintenance of equipment objects. Typically, this is a planned visit by an external expert to ensure that your machine is running properly.

Predictive Maintenance

Predictive maintenance covers all techniques that help determine the condition of the equipment or machine in order to assess when further maintenance is required. This also includes all tools and sensors that track and measure machine performance. Predictive maintenance is only a part of the whole maintenance process and requires further steps, such as condition based maintenance or corrective maintenance.

2. Maintenance

Carry out corrective maintenance after equipment failure or failure. This includes various repairs and replacement of damaged parts. Typically, this is an expensive type of maintenance.

How to provide equipment maintenance efficiency?

There are many ways to improve the maintenance process of the factory. Here are our three suggestions:

1. Develop an effective maintenance plan!

An effective maintenance plan is critical to overall performance and ensures that you can maintain the equipment in normal working condition. An effective maintenance plan should include a description of the work itself: what should be done and how to achieve it? Also include a schedule: When and how often should maintenance be performed? In addition, spare parts, specially trained personnel or contractors may be included in the maintenance plan. The more careful the plan, the more effective it will be.

2. Let your employees receive training to ensure safety!

Another focus is staff training and safety. Ensure that your employees are qualified and trained to perform maintenance tasks quickly and accurately. In addition, provide and inspect appropriate protective equipment as required. Proper development and implementation of maintenance training will help you save money, improve product quality and improve staff morale.

3. Monitor your equipment!

One of our suggestions is about monitoring asset performance. Accurate data and measurements about your machine are essential. They allow you to choose the right maintenance strategy for better and more reliable performance. Otherwise, maintenance concepts such as predictive or condition based maintenance will be meaningless.

DEWETRON -How can we support your maintenance plan?

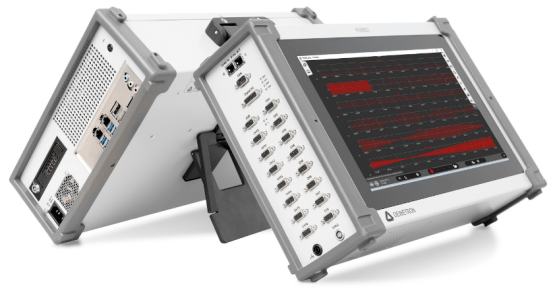

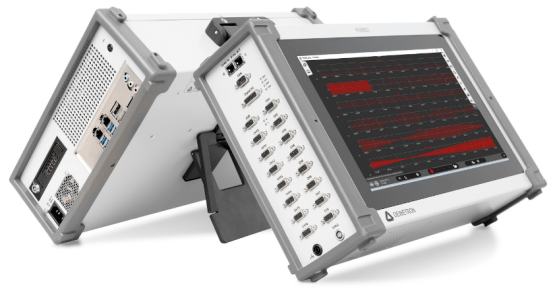

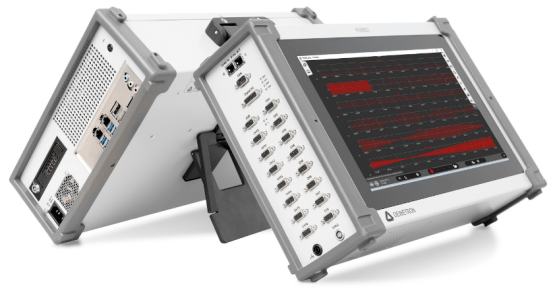

This is where we play a role. We are DEWETRON, a manufacturer of modular and high-precision measuring instruments. Through PU [REC] and NEX [DAQ], we provide you with two perfect solutions for monitoring asset performance.

PU [REC] - our portable, reliable and easy to use power analyzer

PU [REC] - Portable and reliable data recorder

PU [REC] is a portable and expandable data recorder, which is also suitable for harsh environments. In addition to the usual power measurement, PU [REC] can also carry out cloud based monitoring. In this way, the power quality of three-phase resistive capacitive load can be monitored all day. The monitoring process includes:

Data acquisition and signal conditioning are visualized through OXYGEN (DEWETRON's intuitive test and measurement software),

The data is locally stored on the integrated SSD as a 60s file and uploaded to the cloud (connected via Ethernet).

The recorded and saved data can be further viewed and processed with OXYGEN software. Perform various mathematical operations, formulas, filters, statistical analysis, etc.

NEX [DAQ] – Handheld daily operation and maintenance tool

Robust, versatile and compact DAQ Data acquisition system

NEX [DAQ] is a compact and flexible DAQ data acquisition tool for troubleshooting. The USB-C or Ethernet interface connected to any computer becomes a powerful measurement system for various measurement tasks.

In addition, NEX [DAQ] is IP67 certified, which means it will be dustproof and waterproof for a long time. It can be used in the temperature range of - 20 ° C to+70 ° C, because it has no fan, so there is no noise at all. Several NEX [DAQ] units can form a multi-channel system. Only connect them through Ethernet PTP/IEEE1588, and use OXYGEN software to record gapless data.

For more product information, please contact Shanghai Beiying Electronics, an authorized dealer of DVC.